Products.

Products.

Anchor size |

M8 |

M10 |

M12 |

M16 |

M20 |

D(m/m)Drill bit diameter |

10 |

12 |

14 |

18 |

24 |

T(m/m)Embedment depth |

90 |

110 |

125 |

170 |

210 |

ar(mm)Std. distance to edge |

85 |

90 |

120 |

145 |

180 |

a (m/m)Std. distance |

170 |

180 |

240 |

290 |

360 |

d(cm)Min. thickness of base material |

14 |

16 |

17.5 |

22 |

26 |

Rebar size |

#3 |

#4 |

#5 |

#6 |

#7 |

#8 |

#10 |

D(m/m)*Drill bit diameter |

13 |

16 |

20 |

25 |

28 |

32 |

40 |

T(m/m)Embedment depth |

90 |

110 |

125 |

170 |

200 |

225 |

290 |

D(cm)Min. thickness of base material |

14 |

16 |

17.5 |

22 |

24 |

26 |

33 |

hole temperature (℃) |

0。 |

5。 |

10。 |

20。 |

30。 |

40。 |

gel time(Min) |

25 |

20 |

10 |

8 |

4 |

2 |

hardening time(Min) |

180 |

120 |

85 |

45 |

25 |

15 |

hole temperature (℃) |

0。 |

5。 |

10。 |

20。 |

30。 |

40。 |

gel time(Min) |

25 |

20 |

10 |

6 |

4 |

2 |

hardening time(Min) |

180 |

120 |

65 |

45 |

25 |

15 |

Anchor size |

M8 |

M10 |

M12 |

M16 |

M20 |

Recommended load tension Fzul(KN)B30 |

4.8 |

6.2 |

9.5 |

13.0 |

22.0 |

Recommended load shear Qzul(KN)B30 |

4.0 |

6.0 |

9.4 |

13.3 |

21.7 |

Destruction tension (KN)B40 |

- |

45.0 |

56.0 |

63.1 |

104.7 |

V(%) |

- |

7.0 |

5.3 |

9.9 |

17.7 |

|

Rebar size

|

#3(D10)

|

#4(D13)

|

#5(D16)

|

#6(D19)

|

#8(D25)

|

#10(D32)

|

|

Recommended load tension Fzul(KN)B30

|

6.2

|

9.5

|

13.0

|

22.0

|

34.2

|

48.3

|

|

Recommended load shear Qzul(KN)B30

|

6.0

|

9.4

|

13.3

|

21.7

|

32.0

|

52.1

|

|

Average destruction tension

Fu(KN)B30

|

39.0

|

48.6

|

54.7

|

90.8

|

130.9

|

224.3

|

|

Average destruction tension

Fu(KN)B40

|

45.0

|

56.0

|

63.1

|

104.7

|

150.9

|

258.7

|

Rebar size |

#3(D10) |

#4(D13) |

#5(D16) |

#6(D19) |

#8(D25) |

#10(D32) |

Diameter(m/m) |

9.53 |

12.7 |

15.9 |

19.1 |

25.4 |

32.2 |

cross area(㎜2) |

71.3 |

126.7 |

197.9 |

285.0 |

506.7 |

816.5 |

Yield tension(KN) |

20 |

35 |

56 |

120 |

212 |

342 |

Big anti-pulls strengthen, special for heavy installation and anchor.

Fit together with construction ,as if pre-buried , good anti-vibration ,no morals and custom of hole ,no aging ,no acidity ,drill a hole according to your need, no dicey factor of pre-buried.

The influences of side distance and interval distance is small, which is just fitted to use for curtain wall.

Also can be used for hang panel, hang system, stone materials and wet panel, the scope of application is extensive.

Because of use one to one ,it is easy to control the quality of construction.

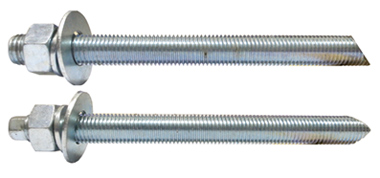

AES --zinc-coated screw pole,IS0898T1 5.8

AESR --stainless screw pole,SUS304

AEG--chemical anchor medicine tube, Epoxy Acrylate,curing agent,quartz and glass tube

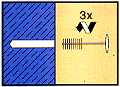

| Anchor size | M8 | M10 | M12 | M16 | M20 | M24 | M30 |

| DB(m/m) Drill bit diameter | 10 | 12 | 14 | 18 | 25 | 28 | 35 |

| T(m/m) Embedment depth | 80 | 90 | 110 | 125 | 170 | 210 | 280 |

| Smax(m/m) Object thickness | 14 | 21 | 28 | 38 | 48 | 54 | 70 |

| L(m/m) Length of Anchor | 110 | 130 | 160 | 190 | 240 | 290 | 380 |

| D(㎝) Min. thickness of base material | 13 | 14 | 16 | 17.5 | 22 | 26 | 33 |

| Mp(Nm)Max. tweak moment | 10 | 20 | 40 | 80 | 150 | 200 | 400 |

| ar (㎝)Std. distance to edge | 10 | 11 | 13.5 | 15.5 | 21 | 26 | 35 |

| a (㎝)Std. distance | 20 | 22 | 27 | 31 | 42 | 52 | 70 |

| base material temperature(℃) | >20℃ | 10~20℃ | 0~10℃ | -5~0℃ |

| hardening time(Min) | 10 | 20 | 60 | 5hrs |

| Anchor size | M8 | M10 | M12 | M16 | M20 | M24 | M30 |

| Allowable force *Fzul(KN)(0℃ to 90℃) | Concrete degree B15 | 2.8 | 4.9 | 7.0 | 10.5 | 18.9 | 25.5 |

| Concrete degree B25 | 4.0 | 7.0 | 10 | 15.0 | 27.0 | 37.0 | |

| Mb(NM) Max. safe working moment | Zinc-coated screw pole | 7.8 | 15.6 | 27.3 | 69.4 | 135 | 234 |

| Stainless screw pole | 9.4 | 18.7 | 32.8 | 83.3 | 162 | 156 | |

| Destruction tension Fu(KN) | Concrete degree B25 | 18.9 | 28.6 | 40.6 | 80.8 | 112 | 131.8 |

High flow ability and easy to use, consist with cement.

Easy, fast and less cost. AC products enhance the nonage and afternoon strength.

No breakaway from material, non-shrinking.

Solve the traditional cement shrink problem, make sure that double side effectual hold and touch.

| Item |

Unit | Result | Test method | |

| Expansion

and shrinkage |

% |

+0.295 |

ASTMC827 |

|

| Flow

value |

%(mm) |

145(245) |

ASTMC230 |

|

| Bleeding |

% |

0.0 |

ASTMC243 |

|

| Compressive

strength |

7 days | Kgf/cm^2 |

469 |

ASTMC109 |

| 28 days | Kgf/cm^2 |

545 |

||

| Bending

strength |

7 days | Kgf/cm^2 |

62 |

ASTMC348 |

| 28 days | Kgf/cm^2 |

91 |

||

| 12 hours | 1 day | 3 days | 7 days | 28 days | 6 months | 1 year | |

| AC100/110 | 41 | 196 | 381 | 469 | 545 | 565 | 586 |

| normal cement | 27 | 81 | 252 | 367 | 422 | 441 | 461 |

cement |

sand |

AC110 |

water |

|

a package of cement |

50kg |

about 50kg |

3.0kg |

about 18.5kg |

each M3 |

830kg |

about 850kg |

50kg |

about 308kg |

|

||||

1. Preparations

The substrate surface should be good clean, mud; small

particles; any impurity shall be remove, than presoaked

for several hours and swept clean of any free water.

If rebar is exposed, concrete must be chipped out all

around and behind 15mm of exposed bar.

(1) Materials

*Cement: Portland cements shall be obtained from suppliers

that have QUALITY ASSURANCE system for product conformity

reviewed without objection by body accredited by Republic

of China Accreditation Service or equivalent.

*Sand: To be chosen such sand with suitable grading

that does not contain a foreign matter such as mud and

salt , and is a hard quality.

*Mixing Water: To be used natural fresh water that does

not contain oil, salt and organic matter.

(2) Cleaning of Concrete Surface

Oil, laitance and mud on the concrete surface should

be removed off before grouting, and saturate thoroughly

the concrete with clean water.

(3) Working place

Avoid vibration in the nearby working place.

2.Form

Forms should be assembled so tightly as to prevent grout

from leaking, and seal the gap with stiff mortar or

soft tape.

3.Set up the injection whole and breathe whole

The injection whole and breathe whole will place in

different side in principle.

Place the injection whole near the bottom of the form,

and seal the contact part of the injection pipe and

the form.

Place the breathe whole near the top of form, and insert

a 30cm length and 3/4” diameter pipe into the form.

Leave 20cm length outside.

4. Mixing Method of Grouting Mortar

A mechanically powered grout high shear vane mixer should

be used for lager quantities.

Accurately measure the correct water quantity (35%~42%

by weight of cement), sand, cement, aggregate into the

mixer. With the mixer running, slowly add the total

contents of the AC-110. Continuously mix for a further

3~5 minutes to ensure that the grout achieves a smooth

state.

The AC100 only need water to mix.

5. Grouting

In grouting work, will be use squeeze machine to grouting

at rate 7.5~30 l/min, start the operation one side by

gravity flow or pumping depending on the situations

of the grouting places, followed by attaining to the

opposite side, so as not to leave any air.

When grouting is performed on the machine base-plate

where vibration is transmitted by running machines nearby,

stop to operate those machines until the initial strength

attained to some 50kg/cm2.

6. Curing

On completion of the grouting operation, exposed areas

should be thoroughly cured. This could be done by continuous

application of water or wet hessian.

7. Finish

Remove the form.

8. Limitations

When the air or contact surface temperatures are 5°C

or below, warm water(30-35°C)is recommended to accelerate

strength development.

For ambient temperatures below 10°C the formwork should

be kept for at least 48 hours.

At night ambient temperatures above 35°C cool water

(15-20°C) should be used for mixing the grout prior

to placement.

9. Care in Storage

Store in dry condition, high temperature and high humidity

location are no ideal place to store the material.

10. Precautions

Gloves and goggles should be worm during mixing and

applying.

If contact with skin occurs, wash with water.

Splashes to eyes should be washed immediately with plenty

of clean water and medical advice sought.

Product 1 : CFRP normal-CFRP patch and epoxy resin bond

Product 2 : CFRP high humidity-CFRP patch and epoxy resin use in high humidity environment

Product 3 : CFRP pre-build-CFRP pre-build plate and epoxy resin bond

Product 4 : CFRP water-type-CFRP slim plate and epoxy resin bond use in water environment

Light weight, slim thickness, work well in small space, and the building can use normally during consturction period.

The patch is soft, it can use in any complex outline component.

CFRP can use in beams, columns, slabs strengthening and etc.

High performance. it can use in anti-bend reinforce, anti-shearing reinforce, and band-bar reinforce.

Acid resistant, alkali resistant, corasion resistant, water resistant, and badness environment resistant.

You can use CFRP in humidity environment and wet surface.

Constructions work well in river, no river flow block need.(CFRP water-type products)

Easy to use, and easy construction quality contral.

Easy to test reinforce performance. (normal test and destructivity test).Easily recover test component if use destructivity test method, and no reinforce performance effect.

Easy to brush up, and easy to maintain.

When do concrete structure, steel structure, wood structure, brick structure need strengthening:

A. Load increase

B. Need more anti-quake strength

C. Structure damaged

D. Defect of structure design or construction

E. Structure system change

F. Improve the structure

|

|

|

|